Main Line Conveyor - Gallery

Frames

Legs

Doors

Coated Doors

Canopies

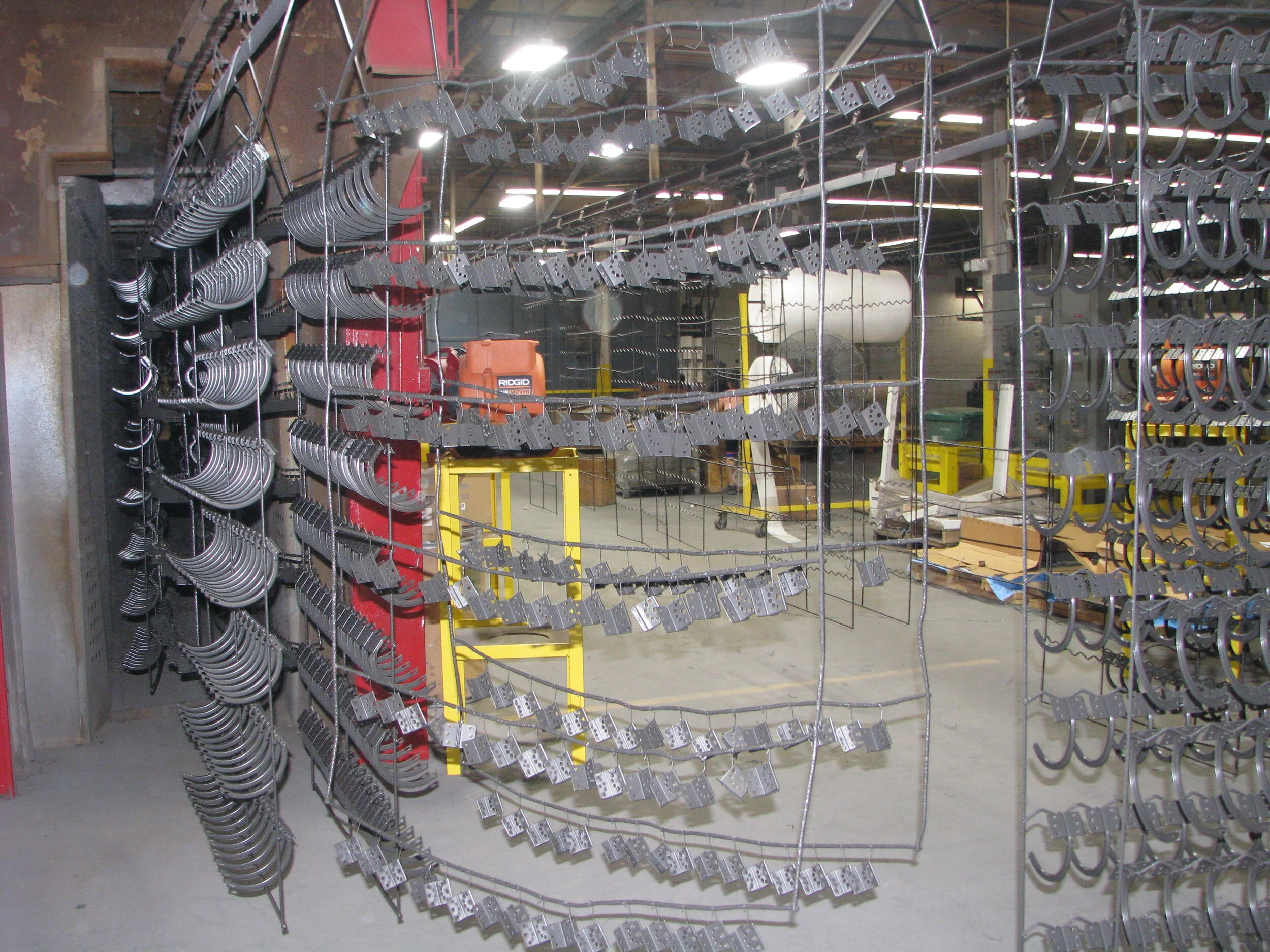

Combos All Hung

Main Line Auto Wash

Main Line Dry Off Oven

Main Line Cure Oven

Coated Combos

Covers

Racks

Poles

Plates

Extrusions

Extrusions

Hang Bars

Poles

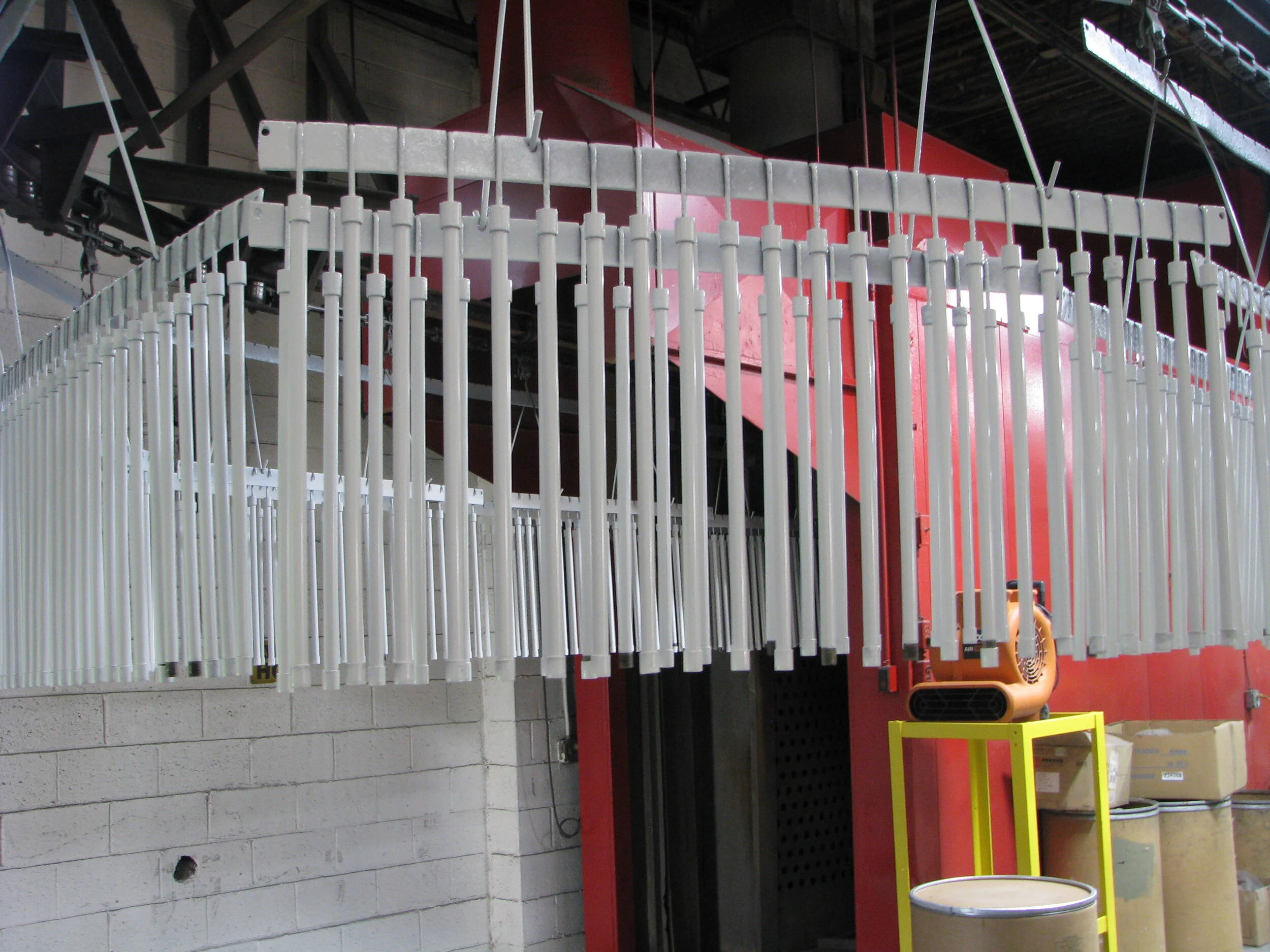

Finished Poles

Main Line Paint Booth

Plates

Reels

Reels

Decorative Panels

Clips

Clip

Poles

Poles